The application

But why should one use pyrogenic silica in the ceramics industry at all? The answer is simple; it can bring great advantages in production and product quality. Based on our long-term customer relationships, we have identified the following core application areas and the resulting benefits:

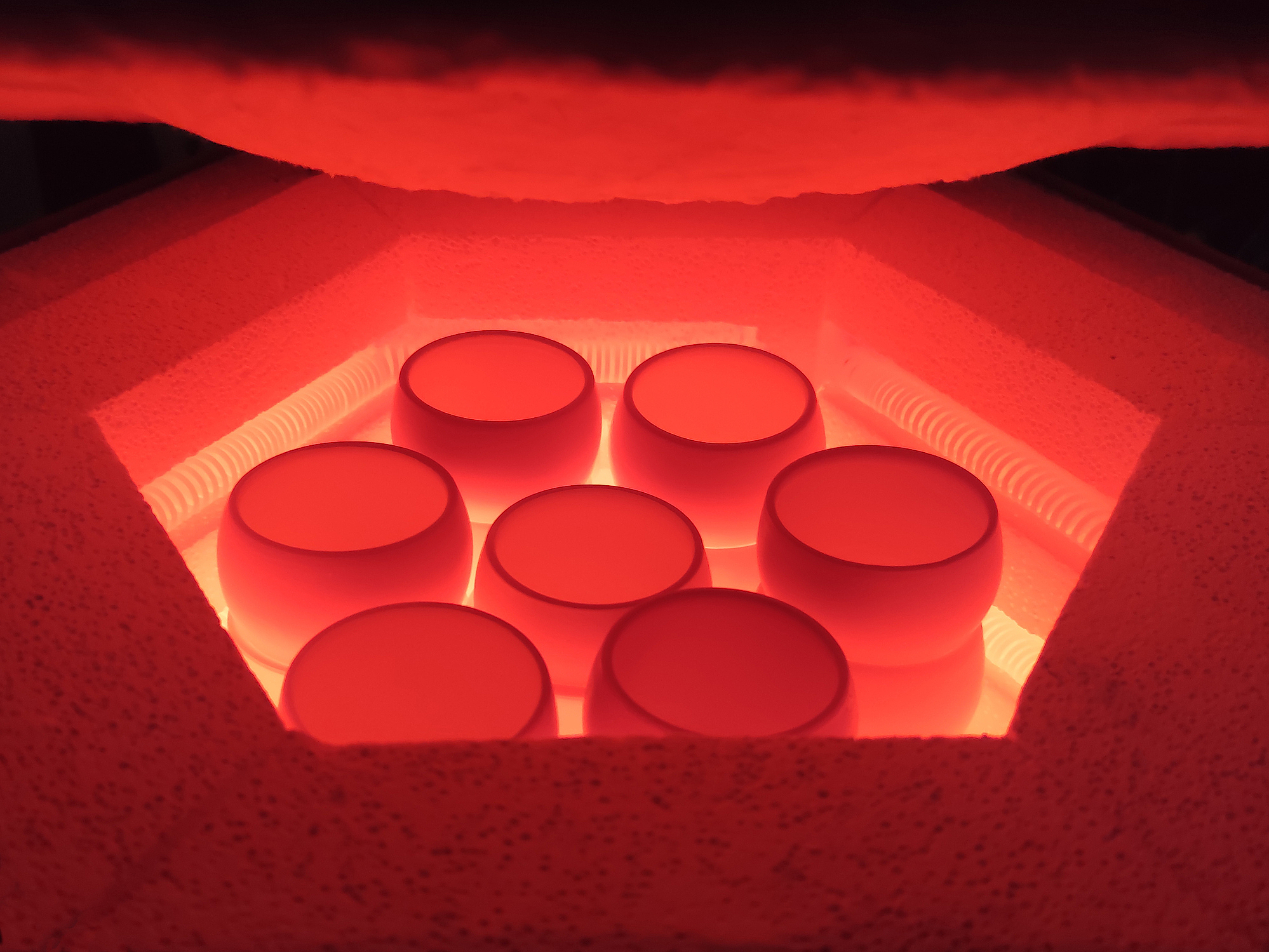

Enhanced Sintering Control:

Guided by its high purity and low specific surface area, ZANDOSIL® enables manufacturers to monitor their sintering process, enhancing the performance, stability, and strength of ceramic products.

Excellent Rheology Control:

Acting as a rheology moderator in the casting process, ZANDOSIL® oversees the viscosity of ceramic slips, thereby ensuring smooth and efficient operations.

Reduced Shrinkage:

Confronting the usual problem of shrinkage during drying and firing processes, ZANDOSIL® effectively mitigates this, preserving the shape and dimensions of the final ceramic product.

Improved Mechanical Strength and Durability:

As a filler and binding agent, ZANDOSIL® bolsters the hardness and durability of ceramic products, adding remarkable value.

Unlock the true potential of your ceramics with ZANDOSIL® pyrogenic silica. Harnessing its remarkable SiO2 purity, chlorine-free assurance, enhanced sintering control, and matrix, ZANDOSIL® empowers you to reach new heights of ceramic excellence. Together, let's master the art of ceramic production.